Basic Info.

Product Description

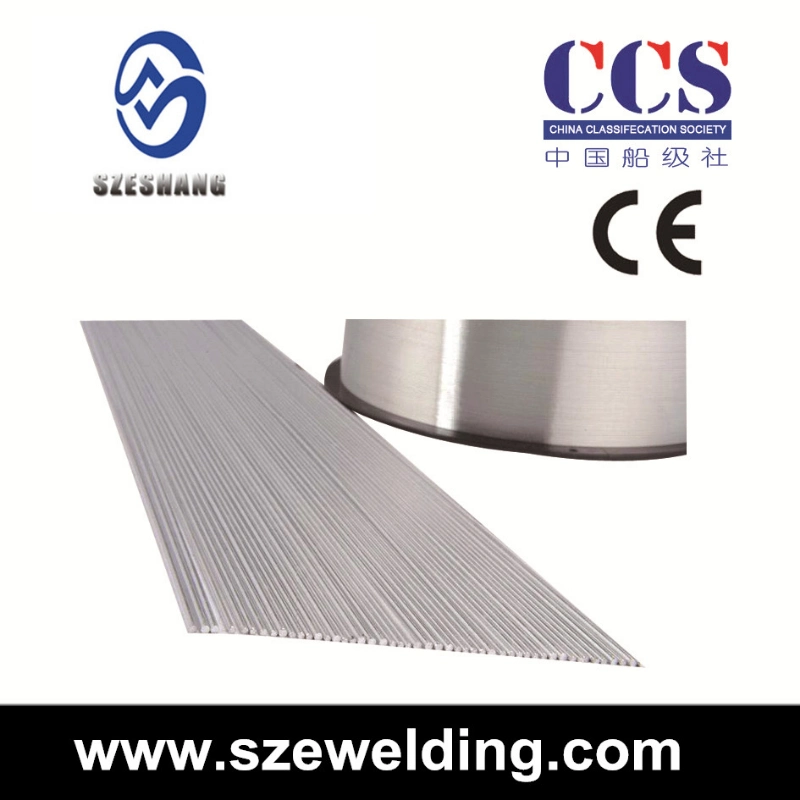

ER308L stainless steel mig and tig welding wire

Product details

| MIG diameter | 0.8mm 0.9mm 1.0mm 1.2mm 1.6mm |

| TIG diameter | 1.6mm 2.0mm 2.4mm 3.0mm 3.2mm 4.0mm |

| Raw material | stainless steel alloy |

| Packing 1 | D100-1kg |

| Packing 2 | D200-5kg |

| Packing 3 | D300-15kg |

| MOQ | 100 kgs |

| Delivery | 5-7 days |

| Product Keywords | ER308L stainless steel mig and tig welding wire for welding |

ER316

Description: ER308 is TIG welding wire for stainless steel. The weld metal is austenitic structure containing 19%Cr-12%Ni-2%Mo, which is excellent in corrosion resistance, heat resistance and crack resistance. Because Mo contains good corrosion resistance to acetic acid, sulfurous acid, phosphoric acid and salts, especially against chloride ion pitting.Uses: Used for the welding of the same type of stainless steel, but also for the welding of high-chromium steel and dissimilar steel without heat treatment after welding.

Item | C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

Standard | ≤0.08 | 0.30- | 1.00- | ≤0.030 | ≤0.030 | 18.00- | 11.00- | 2.00- | ≤0.75 |

Test | 0.048 | 0.43 | 1.78 | 0.012 | 0.010 | 19.23 | 12.5 | 2.52 | 0.30

|

ER316L

Description: ER308L is a TIG welding wire for ultra-low carbon stainless steel. The weld metal is austenitic structure containing 19%Cr-12%Ni-2%Mo, which is excellent in corrosion resistance, heat resistance and crack resistance. Because Mo contains good corrosion resistance to acetic acid, sulfurous acid, phosphoric acid and salts, especially against chloride ion pitting.Uses: Used for welding welding of urea and synthetic fiber equipment. It can also be used for welding high-chromium steel and dissimilar steel without heat treatment after welding.

Item | C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

Standard | ≤0.030 | 0.30- | 1.00- | ≤0.030 | ≤0.030 | 18.00- | 11.00- | 2.00- | ≤0.75 |

Test | 0.022 | 0.42 | 1.89 | 0.009 | 0.007 | 19.12 | 12.62 | 2.62 | 0.34 |

Production process

1. very low welding cost, high productivity and low electricity consumption.

2. excellent welding performance, stable arc, low spatter, easy slag removal.

3. perfect welding seam forming, small weld metal stomatal sensitivity.

4. easy operating, all position welding.

5. very low hydrogen content in the weld and lower nitrogen content, excellent crack-resistance.

6. little deformation after welding.

7. wide applicability. suitable for welding thin, medium and thick plates.

8. Suitably wide range of welding current.

APPLICATIONS:

It can be used in the welding of 12Cr18Ni9 (SUS 302), 06Cr19Ni10 (SUS 304) and other materials.

FEATURES:

The welding wire is 21%Cr-10%Ni austenitic stainless steel welding wire, with stable welding arc and beautiful shape. And it can be used for all position welding.

PRECAUTIONS:

1.Clear rust, oil, water and other impurities on the weldments before welding.

2.It is recommended to use Ar+(1%-3%)O2 as shielding gas in MIG welding, and use pure argon as shielding gas inTIG welding.

3.The user should develop an appropriate production welding specifications acccording to the circumstances.

Our Production Line:

The package of Stainless Steel Welding Wire: 1kg or 6~7kg/carton.

We assist in Beijing Essen Welding&Cutting Fair each year.

FAQ

Q1: Can I have a sample for testing?

A: Yes, we can support free sample

Q2: Can I add my logo on the boxes/cartons?

A: Yes, OEM and ODM are available from us.

Q 3: What are the benefits of being a distributor?

A: Special discount Marketing protection

Q4: Do you have inspection procedures for welding wires?

A: 100% self-inspection before packing. We provide Quality Certification for every order.

Q5: Can we mix itmes in one 20FT container?

A: Yes

Q6: Can I have a visit to your factory before the order?

A: Sure, welcome your visit of factory.