- Overview

- Detailed Photos

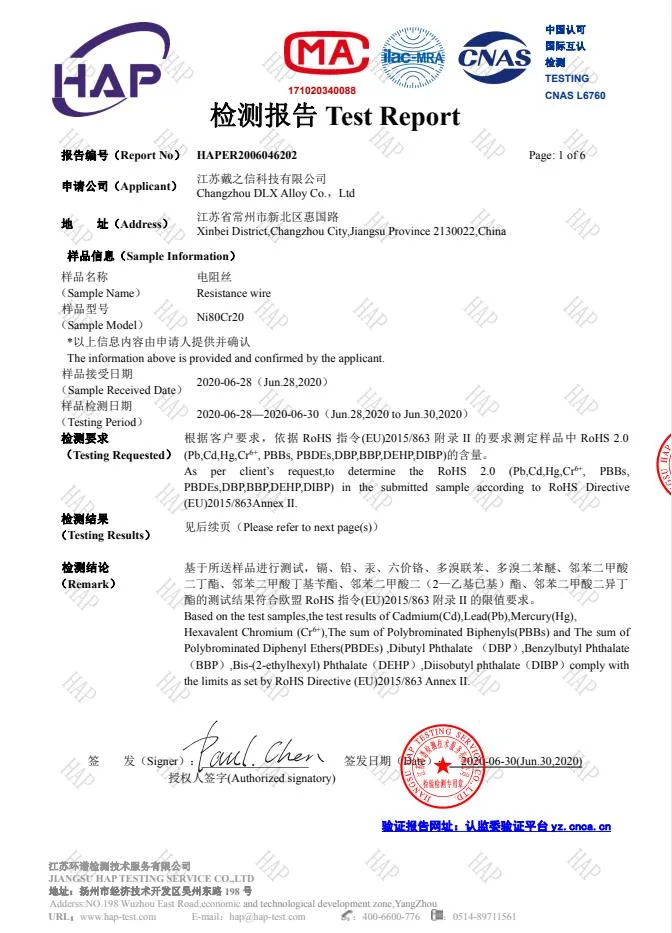

- Certifications

- Company Profile

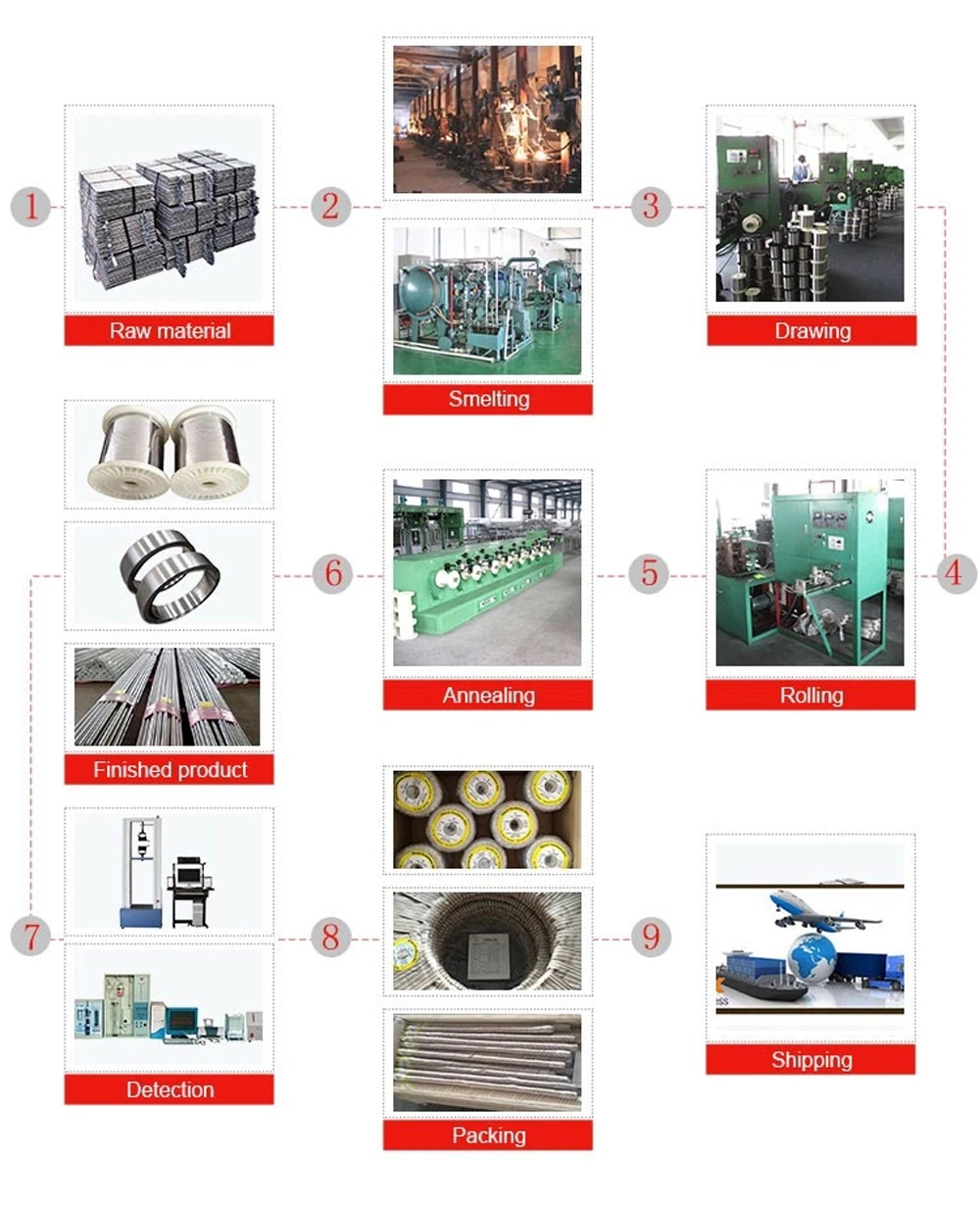

- Packaging & Shipping

- FAQ

Basic Info.

Product Description

The material NiCr8020 with the material number 2.4869 is applied in the form of strips, sheets, tubes and wires for furnace construction components and heating conductors.

It is a nickel-chromium heating conductor alloy for operating temperatures of up to 1150 °C and often contains additives of rare earths for a higher resistance to oxidation, especially with frequent switching operations or broad temperature variations.

The resistance to atmospheric corrosion at 20 °C is high up to the upper operating temperature the resistance to air and other oxygen-containing gases as well as to nitrogen-containing low-oxygen gases is high as well, yet it is low to oxidizing as well as reducing gases containing sulphur.

The resistance to carbonizing is high. Application for industrial electric furnaces, enamelling furnaces, household appliances, night-current storage space-heaters.

| Chemical Composition and Propertes: | |||||

| Propertes/Grade | NiCr 80/20 | NiCr 70/30 | NiCr 60/15 | ||

| Main Chemical Composition(%) | Ni | Bal. | Bal. | 55.0-61.0 | |

| Cr | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | ||

| Fe | ≤ 1.0 | ≤ 1.0 | Bal. | ||

| Max Working Temperature(ºC) | 1200 | 1250 | 1150 | ||

| Resistivity at 20ºC(μ Ω · m) | 1.09 | 1.18 | 1.12 | ||

| Density(g/cm3) | 8.4 | 8.1 | 8.2 | ||

| Thermal Conductivity(KJ/m· h· ºC) | 60.3 | 45.2 | 45.2 | ||

| Coefficient of Thermal Expansion(α × 10-6/ºC) | 18 | 17 | 17 | ||

| Melting Point(ºC) | 1400 | 1380 | 1390 | ||

| Elongation(%) | > 20 | > 20 | > 20 | ||

| Micrographic Structure | austenite | austenite | austenite | ||

| Magnetic Property | nonmagnetic | nonmagnetic | nonmagnetic | ||

| Propertes/Grade | NiCr 35/20 | NiCr 30/20 | Karma | Evanohm | |

| Main Chemical | Ni | 34.0-37.0 | 30.0-34.0 | Bal | Bal |

| Composition(%) | Cr | 18.0-21.0 | 18.0-21.0 | 19.0-21.5 | 19.0-21.5 |

| Fe | Bal. | Bal. | 2.0-3.0 | - | |

| Max Working Temperature(ºC) | 1100 | 1100 | 300 | 1400 | |

| Resistivity at 20ºC | 1.04 | 1.04 | 1.33 | 1.33 | |

| (μ Ω · m) | |||||

| Density(g/cm3) | 7.9 | 7.9 | 8.1 | 8.1 | |

| Thermal Conductivity | 43.8 | 43.8 | 46 | 46 | |

| (KJ/m· h· ºC) | |||||

| Coefficient of Thermal | 19 | 19 | - | - | |

| Expansion(α × 10-6/ºC) | |||||

| Melting Point(ºC) | 1390 | 1390 | 1400 | 1400 | |

| Elongation(%) | > 20 | > 20 | > 20 | > 20 | |

| Micrographic Structure | austenite | austenite | austenite | austenite | |

| Magnetic Property | nonmagnetic | nonmagnetic | nonmagnetic | nonmagnetic | |

Typical Mechanical properties(1.0mm)

- Elongation: 30%

- Yield Strength: 420Mpa

- Tensile Strength: 810Mpa

| Chemical Composition | Nickel 80%, Chrome 20% |

| Condition | Bright/Acid white/Oxidied Color |

| Diameter | 0.018mm~1.6mm in spool, 1.5mm-8mm packing in coil, 8~60mm in rod |

| Nichrome Round Wire | Diameter 0.018mm~10mm |

| Nichrome Ribbon | Width 5~0.5mm, thickness 0.01-2mm |

| Nichrome Strip | Width 450mm~1mm, thickness 0.001m~7mm |

| Diameter | 1.5mm-8mm packing in coil, 8~60mm in rod |

| Grade | Ni80Cr20, Ni70/30, Ni60Cr15, Ni60Cr23, Ni35Cr20Fe, |

| Ni30Cr20 Ni80, Ni70,Ni60, Ni40, | |

| Advantage | The metallurgical structure of nichrome |

| confers them a very good plasticity when cold. | |

| Characteristics | Stable performance; Anti-oxidation; Corrosion resistance; |

| High temperature stability; Excellent coilforming ability; | |

| Uniform and beautiful surface condition without spots. | |

| Usage | Resistance heating elements;Material in metallurgy, |

| Household appliances;Mechanical manufacturing and | |

| other industries. |

| Resistance Wires | ||

| RW30 | W.Nr 1.4864 | Nickel 37%, Chrome 18%, Iron 45% |

| RW41 | UNS N07041 | Nickel 50%, Chrome 19%, Cobalt 11%, Molybdenum 10%, Titanium 3% |

| RW45 | W.Nr 2.0842 | Nickel 45%, Copper 55% |

| RW60 | W.Nr 2.4867 | Nickel 60%, Chrome 16%, Iron 24% |

| RW60 | UNS NO6004 | Nickel 60%, Chrome 16%, Iron 24% |

| RW80 | W.Nr 2.4869 | Nickel 80%, Chrome 20% |

| RW80 | UNS NO6003 | Nickel 80%, Chrome 20% |

| RW125 | W.Nr 1.4725 | Iron BAL, Chrome 19%, Aluminium 3% |

| RW145 | W.Nr 1.4767 | Iron BAL, Chrome 20%, Aluminium 5% |

| RW155 | Iron BAL, Chrome 27%, Aluminium 7%, Molybdenum 2% | |

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples.

2, We can provide the products within a week after payment.

3, Wecan provide sample of the products customer need.

4, We always insist on "Quality first, Customer first" as our business philosophy.

Question: Are you a trading company or manufacturer?

Answer: We're manufacturer.

Question: could we visit your factory?

Answer: Sure, factory visit is warmly welcome.