Basic Info.

Product Description

ER308 stainless steel welding wire and rod For Argon Arc Welding

Description:

ER308 contains low carbon material that reduces the possibility of intergranular carbide precipitation. This increases the resistance to intergranular corrosion without the use of stabilizers such as niobium or titanium. ER308L wire is designed for welding and overlay of base metals similar in composition, such as 304L. 308L is well suited for applications in the chemical and petrochemical industries, distilleries, dairy, and restaurant equipment; and in applications where a good atmospheric corrosion resistance is needed.

Available sizes and diameters and packing details:

| MIG diameter | 0.8mm 0.9mm 1.0mm 1.2mm 1.6mm |

| TIG diameter | 1.6mm 2.0mm 2.4mm 3.0mm 3.2mm 4.0mm |

| Raw material | stainless steel alloy |

| MIG Packing | 1kg/spool, 5kg/spool, 7kg/spool/15kg/spool |

| TIG packing | 5kg/plastic tube |

Chemical Compositions of Stainless Steel Welding Wire:

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | |

| 304 | 0.08 | 0.30-1.00 | 2.00 | 0.045 | 0.030 | 18.00-20.00 | 8.00-11.00 | 0.18 | 0.003 |

| 304L | 0.03 | 0.30-1.00 | 2.00 | 0.045 | 0.030 | 18.00-20.00 | 8.00-12.00 | ||

| ER307 | 0.04-0.14 | 0.30-0.65 | 4.30-4.75 | 0.030 | 0.030 | 19.50-22.00 | 8.00-10.70 | 0.5-1.5 | 0.75 |

| ER308 | 0.08 | 0.30-0.65 | 4.30-4.75 | 0.030 | 0.030 | 19.50-22.00 | 9.00-11.00 | 0.75 | 0.75 |

| ER308L | 0.03 | 0.30-0.65 | 1.50-2.30 | 0.03 | 0.02 | 19.5-21.5 | 9.00-11.00 | 0.75 | 0.75 |

| ER308LSi | 0.03 | 0.65-1.00 | 1.60-2.40 | 0.03 | 0.02 | 19.5-21.5 | 9.0-11.0 | 0.75 | 0.75 |

| ER309 | 0.12 | 0.30-0.65 | 1.00-2.50 | 0.03 | 0.03 | 24.0-25.0 | 12.0-14.0 | 0.75 | 0.75 |

| ER309L | 0.03 | 0.3-0.65 | 1.5-2.3 | 0.03 | 0.02 | 23.0-25.0 | 12.0-14.0 | 0.75 | 0.75 |

| ER309LSi | 0.03 | 0.65-1.0 | 1.6-2.4 | 0.03 | 0.02 | 23.0-25.0 | 12.0-14.0 | 0.75 | 0.75 |

| ER316 | 0.08 | 0.3-0.65 | 1.0-2.5 | 0.03 | 0.03 | 18.00-12.00 | 11.0-14.0 | 2.0-3.0 | 0.75 |

| ER316L | 0.03 | 0.3-0.65 | 1.5-2.3 | 0.03 | 0.02 | 18.0-20.0 | 11.0-13.0 | 2.05-2.55 | 0.75 |

| ER316LSi | 0.03 | 0.65-1.0 | 1.6-2.4 | 0.03 | 0.02 | 18.0-20.0 | 11.0-13.0 | 2.05-2.55 | 0.75 |

| ER310 | 0.08-0.15 | 0.3-0.65 | 1.0-2.5 | 0.03 | 0.03 | 25.0-28.0 | 20.0-22.5 | 0.75 | 0.75 |

| ER347 | 0.08 | 0.3-0.65 | 1.0-2.5 | 0.03 | 0.03 | 19.0-21.5 | 9.0-11.0 | 0.75 | 0.75 |

| ER317 | 0.08 | 0.3-0.65 | 1.0-2.5 | 0.03 | 0.01 | 18.5-20.5 | 13.0-15.0 | 3.0-4.0 | 0.75 |

| ER321 | 0.08 | 0.3-0.65 | 1.5-2.5 | 0.03 | 0.01 | 18.5-20.5 | 9.0-10.5 | 0.75 | 0.75 |

Mechanical Properties of Welding Wire:

| Tensile strength Rm(Mpa) | Yield strength Rel or Rp0.2(Mpa) | Elongation(%) | Tensile strength Rm(Mpa) | Yield strength Rel or Rp0.2(Mpa) | Elongation(%) | ||

| 304 | 550 | -- | 25 | ER309LSi | 510 | 320 | 25 |

| 304L | 510 | -- | 25 | ER316 | 510 | 320 | 25 |

| ER307 | 590 | 350 | 25 | ER316L | 510 | 320 | 25 |

| ER308 | 550 | 350 | 25 | ER316LSi | 510 | 320 | 20 |

| ER308L | 510 | 320 | 25 | ER310 | 550 | 350 | 25 |

| ER308LSi | 510 | 320 | 25 | ER347 | 550 | 350 | 25 |

| ER309 | 550 | 350 | 25 | ER317 | 550 | 350 | 25 |

| ER309L | 510 | 320 | 25 | ER321 | 550 | 350 | 25 |

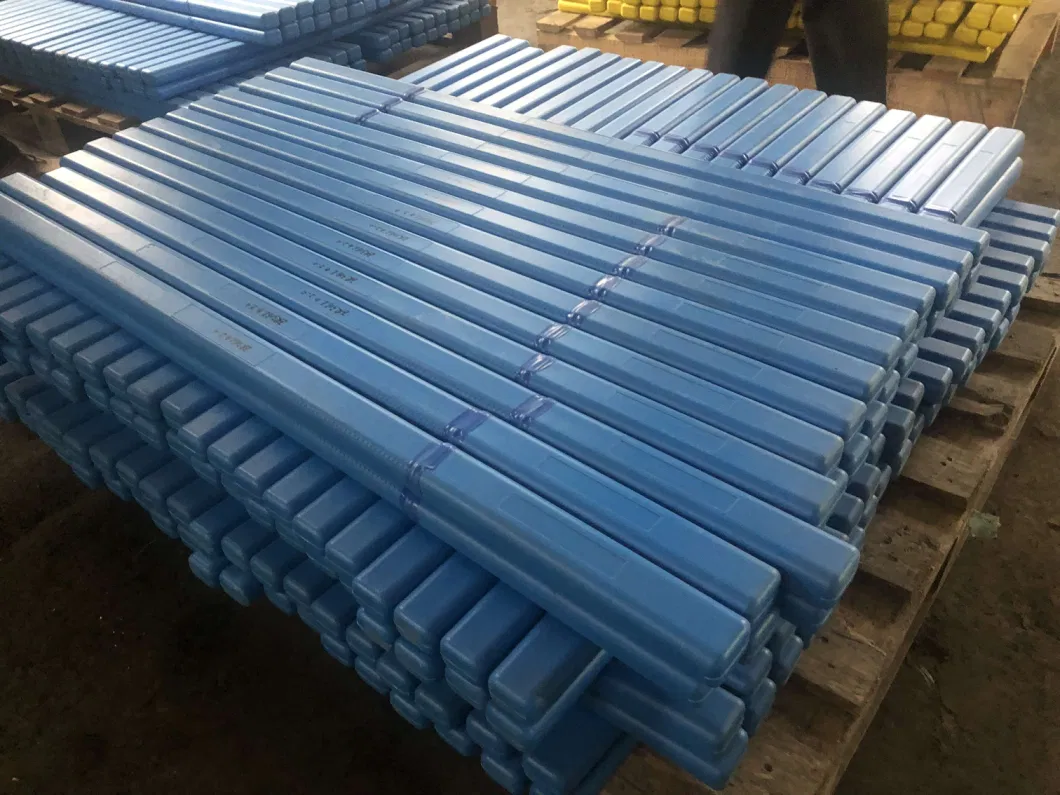

Product pictures

Application

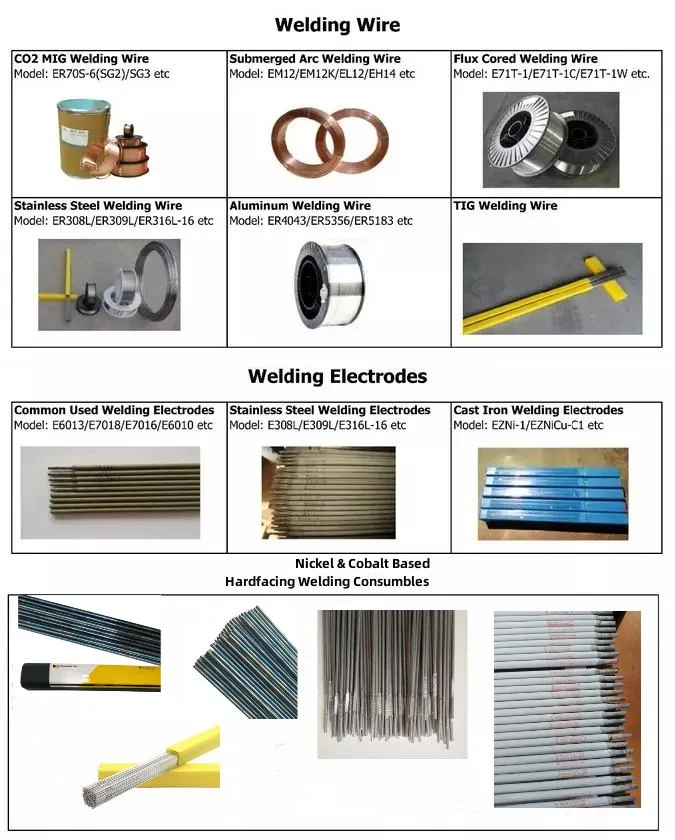

Other products