Basic Info.

Product Description

Er70s-6 Stainless Steel MIG Welding Wires

Product Descriptions:

1)Product Name:Solid Solder ER70S-6 Welding Wire MIG Welding Wire With Copper Coated

2)Standard Grade:GB/T 8110 ER50-6/ AWS A5.18 ER70S-6

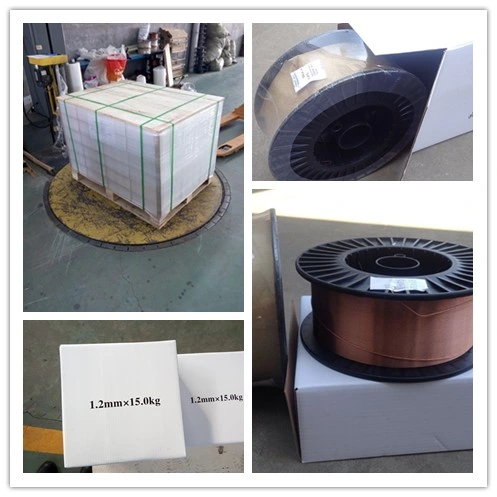

3)Package: Forward Welding Package/Neutral Package/OEM Package

| Available Diameter | 0.8mm, 0.9mm, 1.0mm, 1.2mm, 1.6mm |

| Packing Standard | 5kg/D200 Plastic Spool, 5.6kg/box, 200boxes/pallet, 24pallets/1x20'GP |

| 15kg/D270 Plastic Spool, 16kg/box, 72boxes/pallet, 24pallets/1x20'GP | |

| 250kg/drum, 4drums/pallet, 22Pallets/1x20'GP | |

| 350KG/drum, 2drums/pallet, 28Pallets/1x20'GP |

4)Price Terms: CIF, CFR, FOB

5)Payment Terms: 30% T/T in advance, 70% balance against B/L copy.

L/C at sight.

6)Lead Time: Within 5~25 Days After Receipt Of Payment.

7)MOQ: 22-25 Tons For One Full 20ft Container Load.

Mill Test Certificate

| Commodity | Grade | Size | Batch No | Quantity / Net Weight | Executive Standard | ||||

| WELDING WIRE | ER70S-6 | 0.8mm - 15KG/SPOOL | 16080105 | 504 SPOOL/ 7.56 M.TONS | AWS A5.18:2005 | ||||

| Chemical Composition (%) | Mechanical Properties | Others | |||||||

| Item | Requirement | Test Result | Items | Requirement | Test Result | Item | Requirement | Test Result | |

| C | 0.060-0.150 | 0.0700 | Tensile Strength Rm(MPa) | ≥500 | 534 | Radiographic Inspection | GRADE II | GRADE I | |

| Si | 0.800-1.150 | 0.9400 | |||||||

| Mn | 1.400-1.850 | 1.5400 | Yield Strength Rp0.2(MPa) | ≥420 | 427 | ||||

| P | ≤0.025 | 0.0120 | |||||||

| S | ≤0.025 | 0.0090 | Elongation A(%) | ≥22 | 28 | ||||

| Cr | ≤0.150 | 0.0140 | |||||||

| Ni | ≤0.150 | 0.0080 | V-notch Impact Test | Impact Temp (ºC) | -40 | -40 | |||

| Mo | ≤0.150 | 0.0016 | |||||||

| V | ≤0.030 | 0.0015 | Absorbed Energy (J) | ≥27 | 80 | ||||

| Al | ≤0.020 | 0.0040 | 80 | ||||||

| Ti+Zr | ≤0.150 | 0.0038 | |||||||

| Cu | ≤0.500 | 0.1600 | 80 | ||||||

| Surface: Qualified | |||||||||

| Welding Processes: make sure the flat and beautiful welding seam, not undercutting, with the stable arc easy control, smokeless and little splash, high efficiency of depositing. | |||||||||

| WE HEREBY CERTIFY THAT THIS REPORT IS CORRECT AND THAT ALL TEST RESULTS ARE IN COMPLIANCE WITH THE SPECIFICATION DESCRIPED HEREIN. | |||||||||

TOP TIPS

| Important Tips | 1. Remove the rust, oil, moisture and other impurities from base metal. | ||

| How to Stock! | 2. Welding heat input will directly affect the mechanical perties of welds. | ||

| 2-1. Welding heat input depends on the importance of struture. | |||

| 2-2. The more important the structure is, the smaller the welding heat input | |||

Main Applications:

widely used for welding steel structure

√ coal mine machinery,

√ ships,

√ engineering machinery,

√ bridges,

√ pressure vessels,

√ building construction,

√ strength 500MPa welding parts etc.

Excellent Performances:

| Features | 500MPa Grade Carbon Steel Wire | ||

| ★ 100% CO2 or Ar+CO2 Gas Shield | |||

| ★ Little Spatter | |||

| ★ Beautiful Welding Seam | |||

| ★ High Deposited Efficiency | |||

| ★ For Welding All Positions | |||

Featured Welding Products Catalogue:

1. ER70S-6 CO2 Gas Shielded Welding Wire( ER70S-6/ ER70S-G )

2. MAG Welding Wire ( MAG Wire Solder )

3. MIG Welding Wire ( MIG Wire Solder )

4. TIG Welding Wire (TIG Wire Solder )

5. AWS ER70S-G Welding Wire

6. AWS EL12 H08A Submerged Arc Welding Wire ( EL12 SAW Wire )

7. AWS EH14 H10Mn2 Submerged Arc Welding Wire ( EH14 SAW Wire )

8. AWS EM12 H08MnA Submerged Arc Welding Wire ( EM12 SAW Wire )

9. Welding Rod/Electode

10.Submerged Arc Welding Flux

FAQ:

1)Are you a factory or a trading company?

LaiWu HuLin Welding Materials Co., Ltd. is a professional factory of welding wire&welding flux, at the same time, we have own professional marketing team to expand the overseas market.

2)Is OEM available?

Yes, OEM is available.

3)Is the sample available?

Yes, free samples are available for you to test the quality.

4)Have the products been tested before shipping?

Yes, of course, all of our welding products would have been tested before shipping on board.

The Mill Test Certificate can be provided by our professional test Lab.

5)What's benefit will you bring?

Your clients will be satisfied with the quality and service.

Your can enjoy high reputation from your markets and obtain more orders.

Contact me,let's talk in details: