- Overview

- Product Description

- Product Parameters

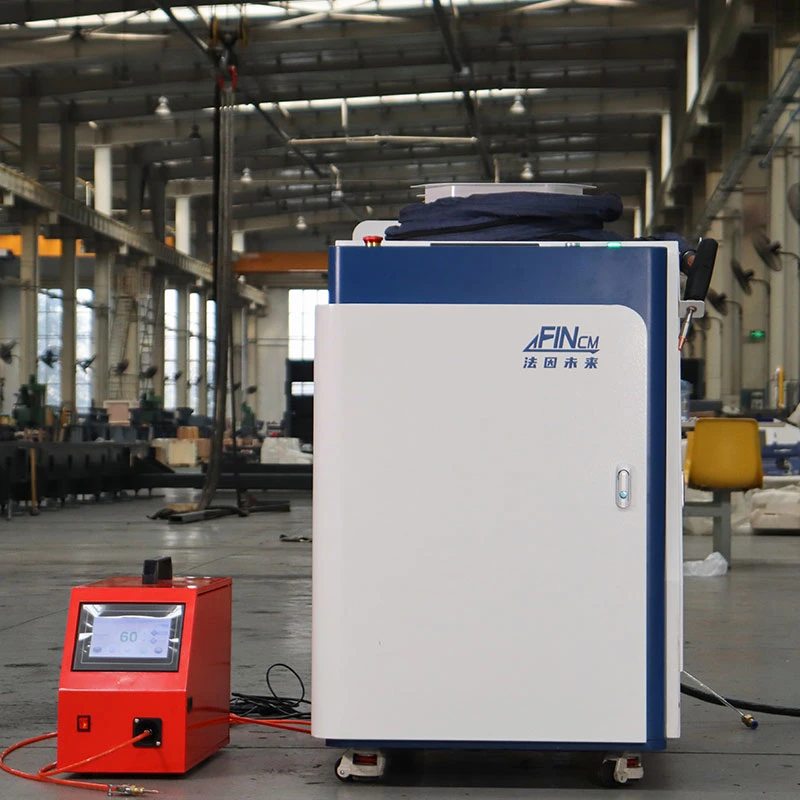

- Detailed Photos

- Company Profile

- Customer Visit

- Certifications

- FAQ

Basic Info.

Product Description

Handheld Fiber Laser Cutting Cleaning Welding Machine

Features:

1) It is easy to install and operate safely

2) Reducing consumable materials when welding, saving cost

3) Fast welding speed, high efficiency and good welding effect

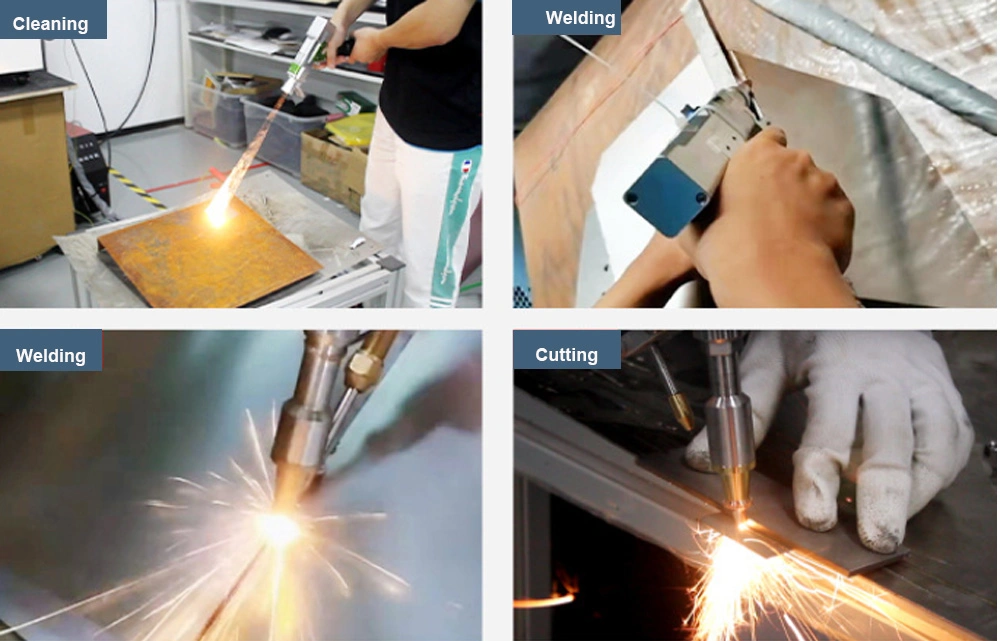

4) It can be used for cutting welding cleaning with one machine by changing different nozzles

- With a power of 1,500 watts/ 2000W/3000W, a laser welder is ideal for precise welding, cutting, and derusting.

- Laser beam welding ensures precise weld seams with low thermal distortion at high welding speeds due to the concentrated energy input into the workpiece. In this way, perfect work results can be achieved in a short time.

- Thanks to its lightweight and compact design, the multifunctional laser welder is ideal for mobile use in industry, crafts and DIY.

| Laser Welder | MIG and TIG Welder | |

| Speed and Productivity | Fiber laser welding is generally faster than MIG and TIG welding, especially for thin materials. The concentrated heat source allows for quick and efficient welding, contributing to higher productivity. | MIG and TIG welding processes can be slower compared to fiber laser welding,but they are versatile and suitable for a wide range of applications. |

| Precision and Accuracy | Fiber laser welding offers high precision and accuracy due to its focused and concentrated beam. It is suitable for applications requiring fine control over the weld. | MIG and TIG welding can provide good precision, particularly with skilled welders, but the level of precision may not match that of fiber laser welding. |

| Heat Input and Distortion | Fiber laser welding typically results in a smaller heat-affected zone, reducing distortion and minimizing thermal stress on the workpiece. | MIG and TIG welding introduce more heat into the workpiece compared to fiber laser welding, which can lead to a larger heat-affected zone and increased distortion, especially in thicker materials. |

| Automation and Integration | Fiber laser welding can be easily integrated into automated production processes, enhancing efficiency and repeatability. | MIG and TIG welding processes can also be automated, but the level of automation may vary based on the specific application. |

| Model | FW-1500 | FW-2000 | FW-3000 | |

| Power | 1500W | 2000W | 3000W | |

| Weld Thickness (Recommended) | Stainless Steel | 0.5-4mm | 0.6-6mm | 0.6-8mm |

| Carbon Steel | 0.5-4mm | 0.6-6mm | 0.6-9mm | |

| Aluminum Alloy | 0.5-4mm | 0.6-6mm | 0.6-10mm | |

| Galvanized Sheet | 0.5-4mm | 0.6-6mm | 0.6-11mm | |

| Welded Materials | Stainless steel, carbon steel, aluminum ,galvanized sheet, copper | |||

| Laser Wavelength | 1080 ± 10 nm | |||

| Size | 51.18 inch*24.41 inch*47.24inch /1300mm*620mm*1200mm | |||

| Spot Adjustment | 0.2mm-5mm | |||

| Collimated Focal Length | 60mm | |||

| Focus Focal Length | 150mm | |||

| Laser Power Brand | Max /Raycus/Customized | |||

| Mode of Operation | CW/Pulse | |||

| Welding Joint Interface | QBH | |||

| Fiber Wire Length | 10m/15m/20m | |||

| Cooling Method | Water Cooling | |||

| Positioning | Red Pointer | |||

| Auto Wire-feeder | Standard | |||

| Wire Feeding Diameter (mm) | 0.8/1.0/1.2/1.6/2.0 | |||

| Voltage | 220±20% VAC 50/60Hz / 380±20% V AC 50/60Hz | |||

| Welding Speed | 0~120 mm/s | |||

| Laser Gun Weight | 0.8KG | |||

| Laser Head | Cleaning/Cutting/Welding/Weld Seam Cleaning | |||

Full touch screen operation interface, adjustable at any time

1. The internal design is dexterous and has a good interactive control system, which expands the tolerance range of processing parts and weld width, solves the disadvantage of small light spot, and improves the weld forming.

2. It is light in shape and comfortable in grip with ergonomic design method. It is easy to master and operate.

3. With multiple safety alarms, the light will be automatically locked after the workpiece is removed, with high safety.

4. The welding seam is beautiful and fast, and there is no need to polish after welding.

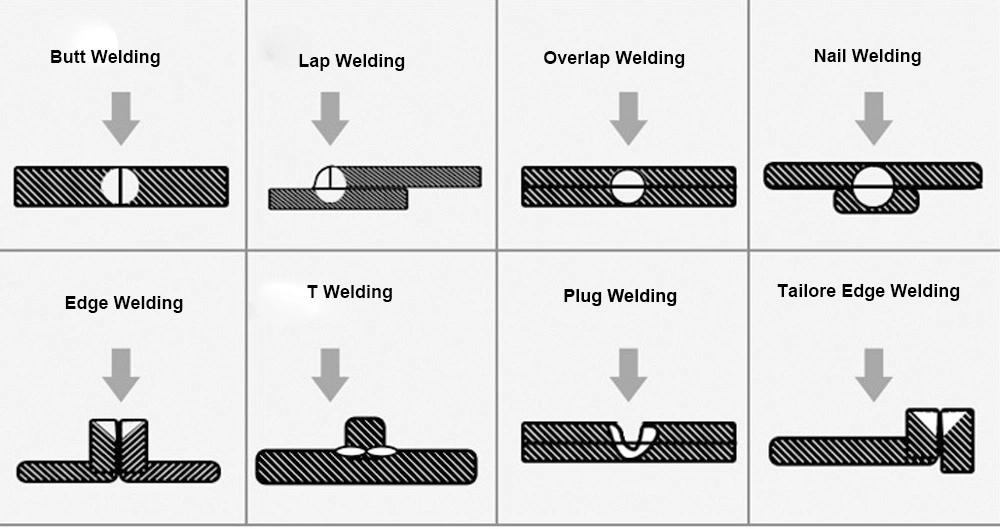

5. It can be equipped with wire nozzle components and copper nozzles with various angles to meet the welding requirements of different products.

2. MAX/RAYCUS/IPG/CUSTOMIZED

3 IN 1 : CUTTING WELDING CLEANING

Contact us and get more details about free gifts:

Samples Show

Shandong FINCM Future Intelligent Manufacturing Co., Ltd is a large-scale manufacturing enterprise dedicated to laser industrial application solutions, specializing in the research and development, production and sales of laser equipment.

It is committed to realizing the cutting, welding, and cladding of metal materials such as profiles, plates, and pipes, as well as the cutting and engraving of non-metallic materials. Our products mainly include laser cutting machines, fiber laser cutting machines, laser pipe cutting machines, ground rail laser cutting machines, H-beams laser cutting machines, handheld laser welding machines, and non-metallic cutting machines, etc.

In line with the entrepreneurial spirit of "quality first, integrity-based", we will work hard to achieve the goal of "world-renowned equipment and intelligent creation of the future".

Quality Inspection

Please feel free to contact us if you are interested in our factory!

1. Can you tell me the actual address of the company and whether I can visit the factory?

A: Our factory is located in No. 2222, Century Avenue, High-tech Zone, Jinan City, Shandong Province. Warmly welcome to visit our factory.

2. When I got this machine, but I don't know how to use it. What should I do?

A: We will send a video and English manual with the machine firstly. If you still have some doubts, we can talk by telephone or Skype and video connection. Moreover, our after-sales staff will go to your company to assist in the installation and commissioning of equipment if you need it.

3. If some problems happen to this machine during the warranty period, what should I do?

A: We will supply free parts during the machine warranty period if the machine has some problems. We also supply free life-long after-sales service. So any doubts, just let us know and we will give you solutions.